Optical bonding

KOTO Optical Bonding

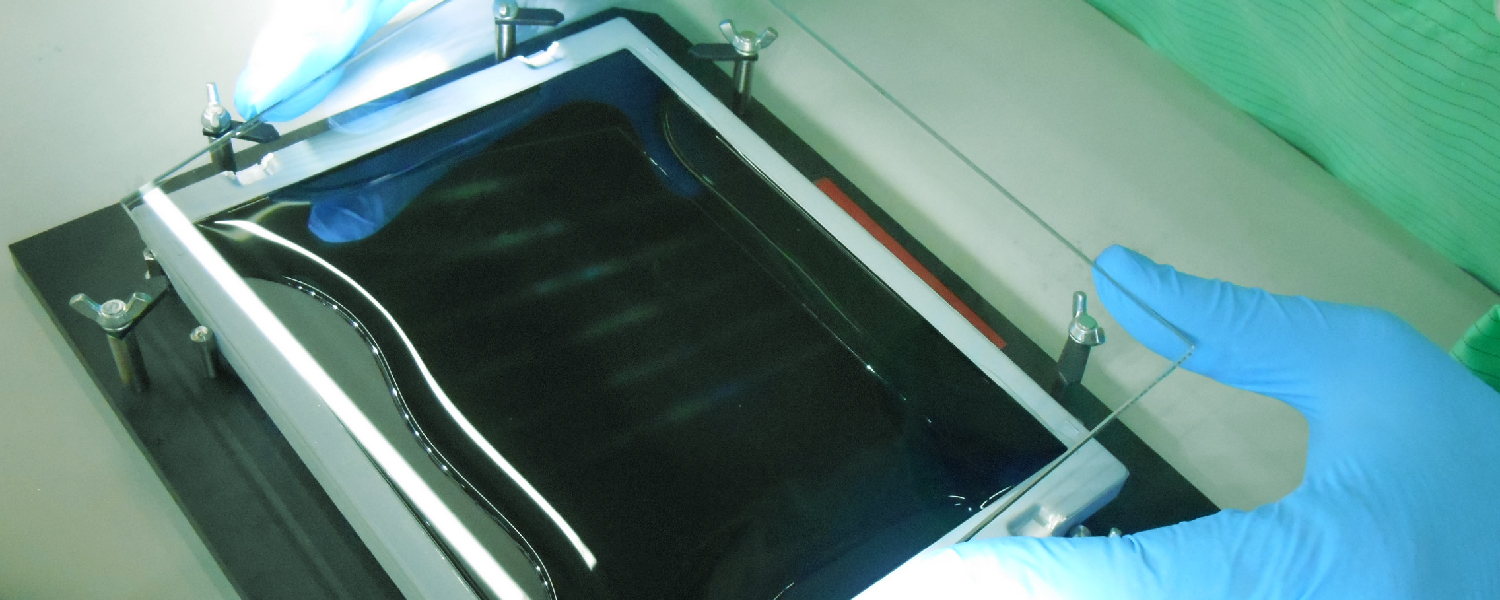

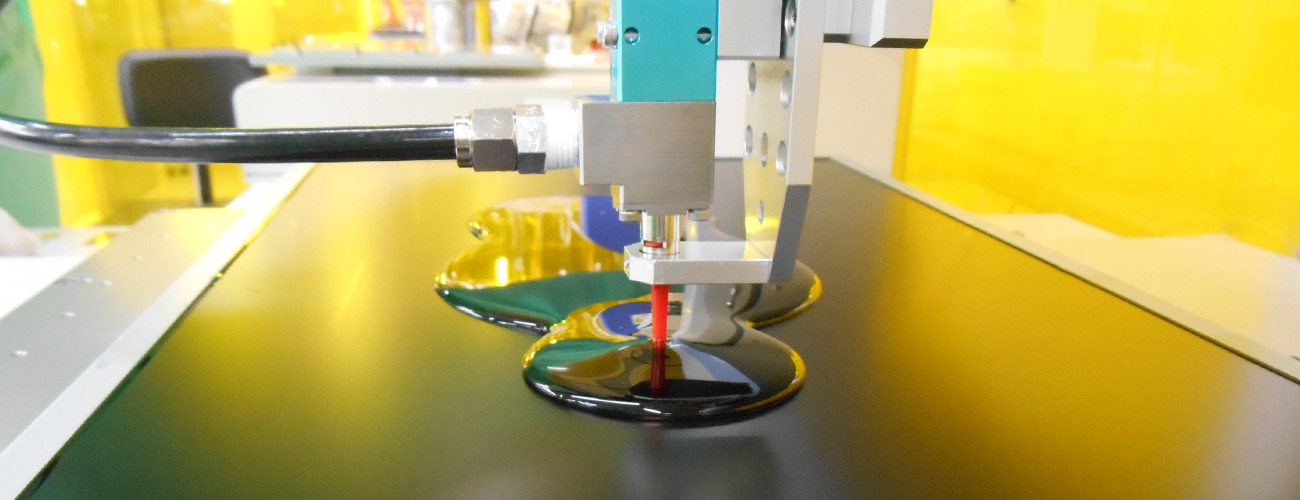

We use UV-curable Liquid Optically Clear Adhesive (UV-LOCA) for our bonding, since UV-LOCA has superior optical properties and is suitable for displays with uneven surfaces such as bezels because it is liquid.

Although the vacuum bonding method or autoclave is often used for LOCA bonding, we perform our bonding in the atmosphere and don't use autoclaves. Our method is well received by the customers who want to avoid any damage to the LCD modules and touch panels.

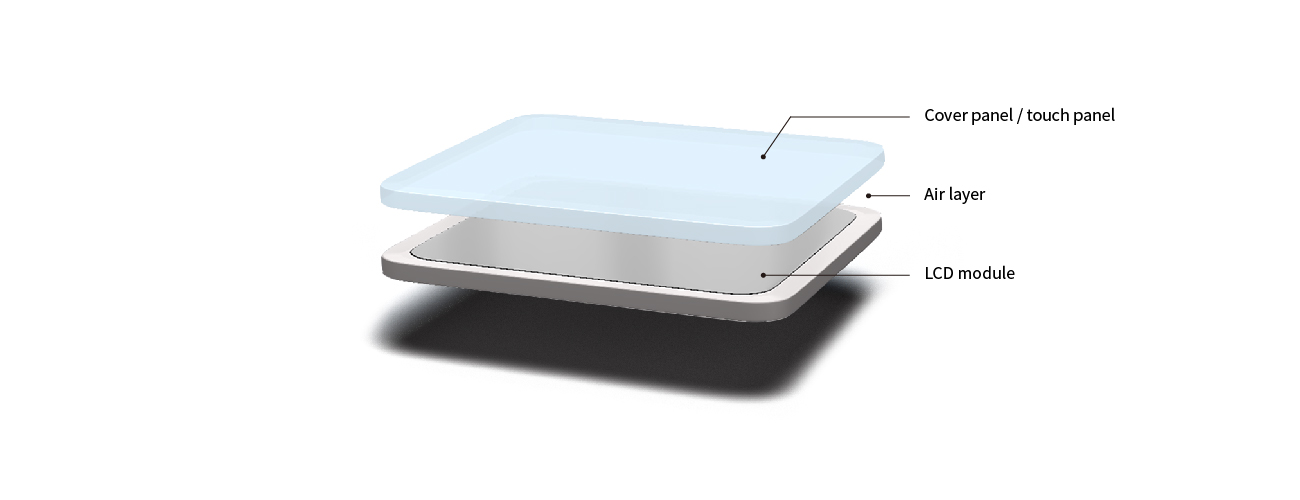

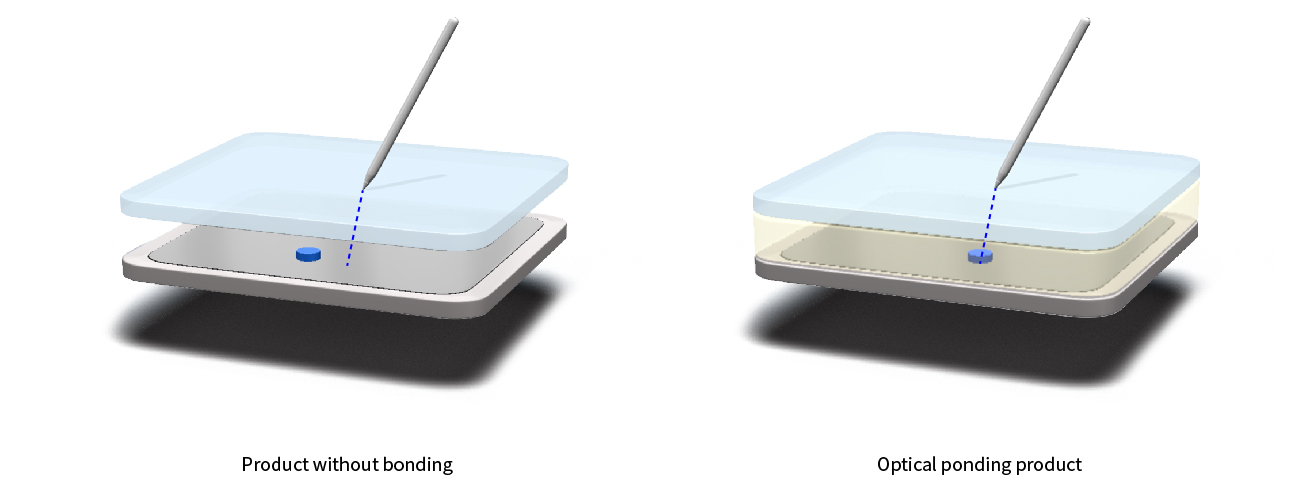

Optical Bonding

There is an air gap between the LCD module and the cover panel or touch panel that protects the surface of the LCD. Optical bonding is a process to fill this gap with optical elasticity resin to bond the LCD and the cover panel or touch panel.

Effects of Optical Bonding

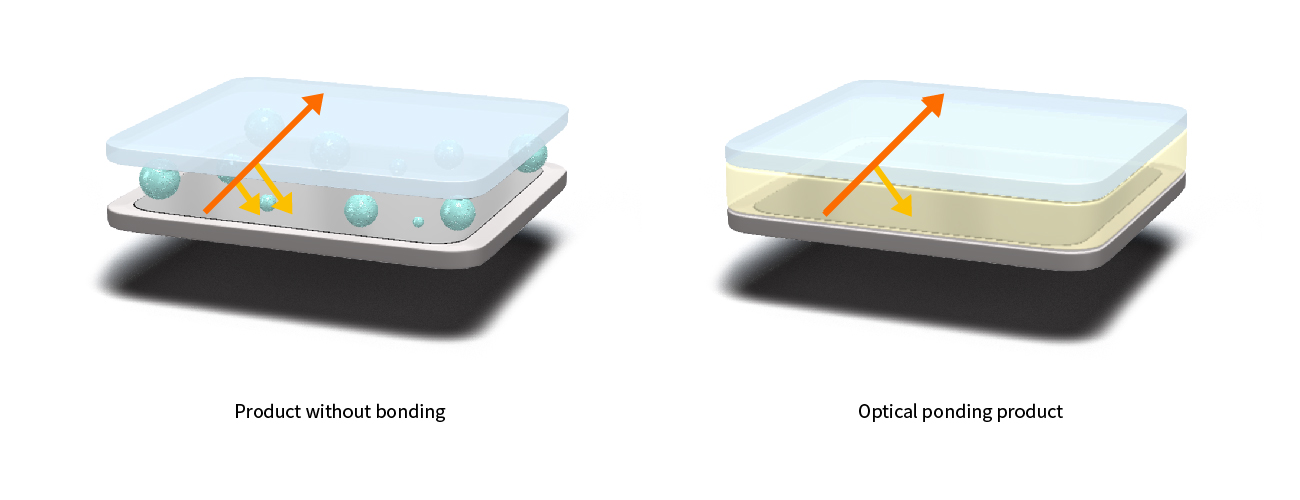

Reflected sunlight, high luminance fluorescence light, and other ambient light on the LCD screen significantly reduce visibility. Optical bonding can minimize such reflection to improve visibility. Other effects include the prevention of condensation and inclusion of foreign substances and improvement of shock resistance.

① Visibility Improvement

The light emitted from the LCD module is displayed through the cover panel and the layer of air. However, passing through the cover panel and the layer of air which have different refractive indices reduces the brightness. Optical bonding can reduce the refraction of light and improve visibility.

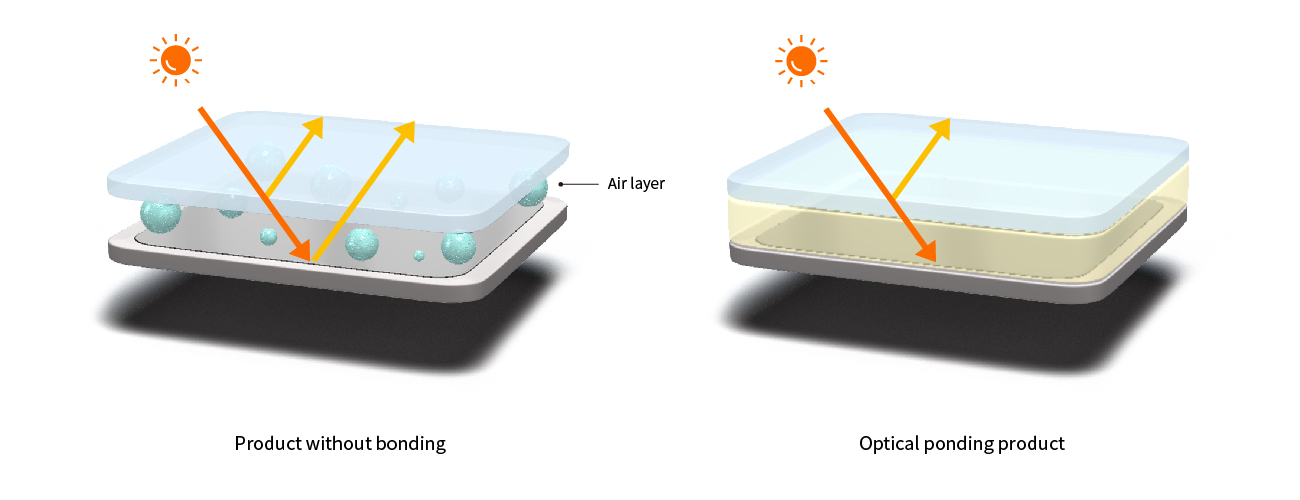

② Reducing the Reflection of Light from Outside

The incident lights from outside (sunlight or high luminance fluorescent light) is reflected on the LCD display, which occurs when the ambient lights having different refractive indices pass through the cover panel or the layer of air. Optical bonding can reduce reflection in the display.

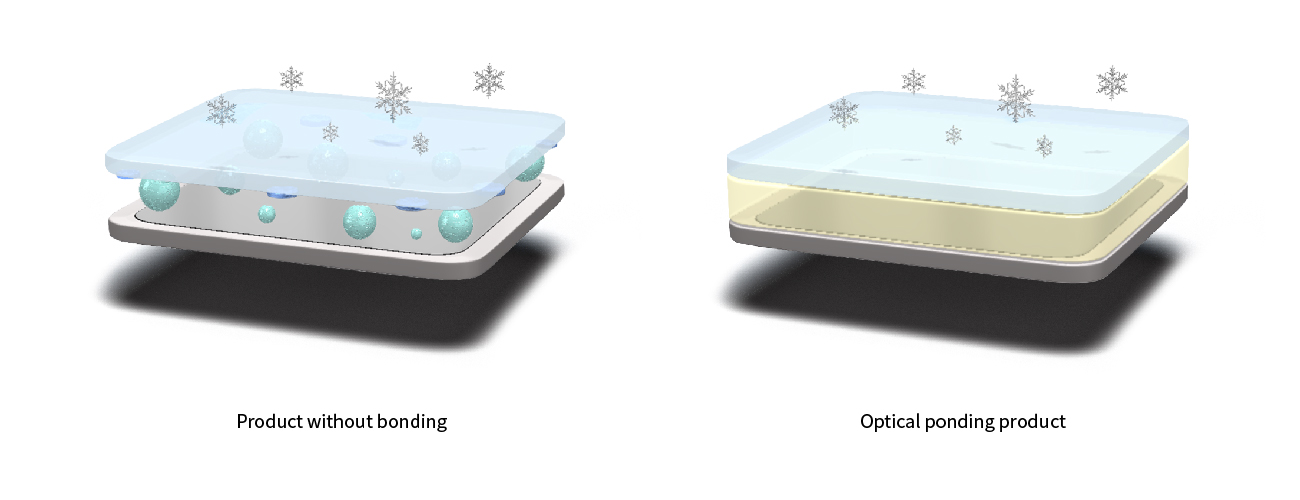

③ Prevention of Condensation

When the LCD module with an air gap between the cover panel and the LCD is used in an environment where temperature changes drastically, dew condensation may occur in the gap. Optical bonding can eliminate this air gap and prevent condensation.

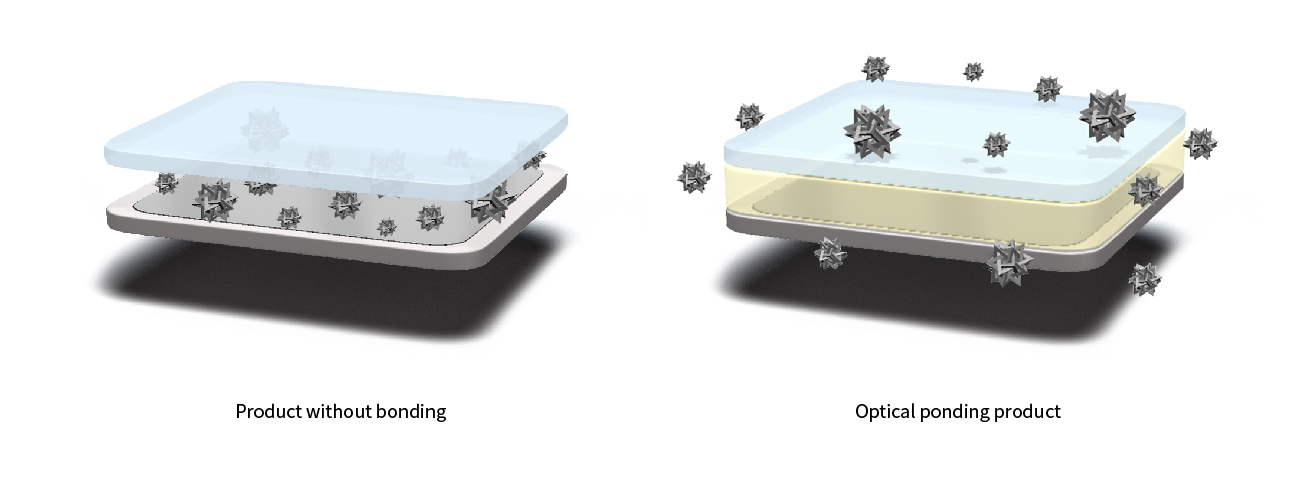

④ Prevention of Inclusion of Foreign Substances

When the LCD module with an air gap between the cover panel and the LCD is used in a factory or outside, foreign matters (dust, fine particles, moisture, etc.) are easy to enter through the gap. Optical bonding can prevent this from happening.

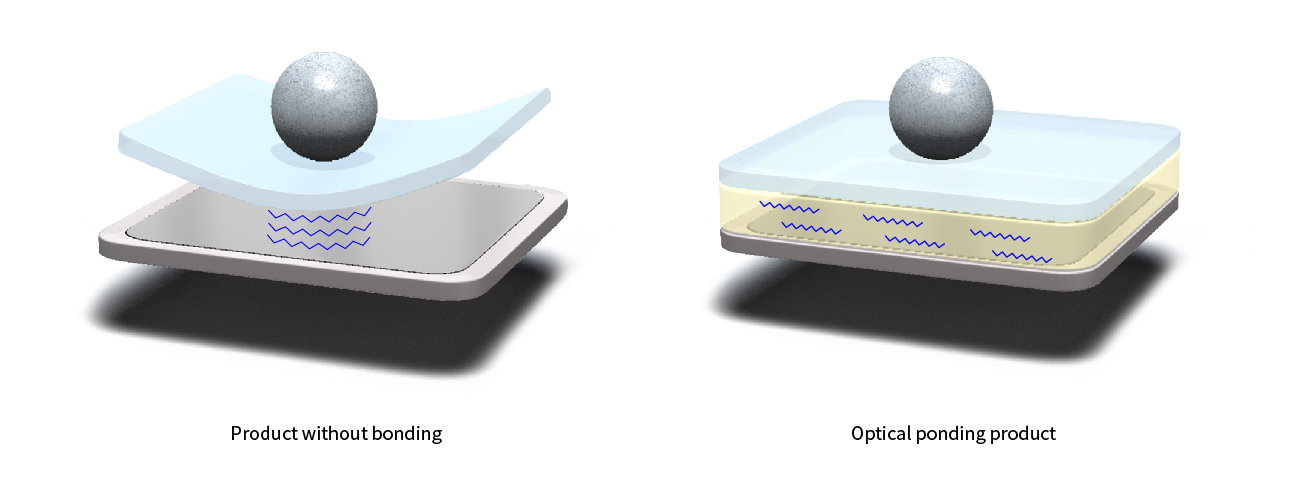

⑤ Improvement of Shock Resistance

The LCD module with an air gap between the cover panel and the LCD is susceptible to physical shock. Filling the gap with the resin can improve the resistance to an external shock.

⑥ Improvement of Operability of Touch Panel

When you operate a touch panel, parallax error or display delay may occur depending on the specification of the touch panel. Optical bonding can improve the operability and enable the smooth operation of the touch panel.

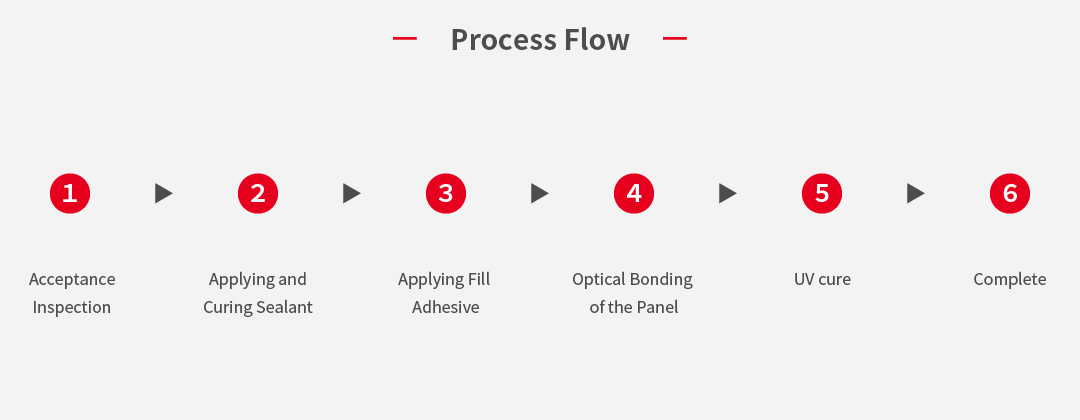

Workflow From Order Acceptance to Delivery

Process Flow

Optically Bonded Applications

Optical bonding is used for the following applications.

Fish finders

Ultrasonic image diagnostic equipment

Airplane cockpit displays

Helicopter displays

Promising Optically Bonded Applications

The use of optical bonding is being expanded. We will see more optically bonded displays for a variety of applications.

ATM display

EV quick charger

FA equipment monitor

Coin parking display

Ultrasonic medical diagnostic equipment

Ticket machine, Food ticket vending machine

Optical Bonding Specifications (Achievements)

| Manufacturer | Multiple manufacturers in and outside Japan |

|---|---|

| Size | 4.3in to 23in wide (Please inquire about other sizes.) |

| Type | Cover glass, Reinforced glass, Resistive touch panel, Capacitive touch panel, Cover glass with decorative print, heater glass. |

|---|---|

| Thickness | 1mm to 5mm (Other thicknesses available) |

| Cover glass surface coating | AR, AG, AF coating, Decorative printing, ITO coating, etc. |

We are happy to receive inquiries about other specifications. Do you want to color the LOCA for better design? Do you want to use LOCA that reduces the blue light from the display which is friendly to eye? Do you want to block UV light to protect the LCD for outdoor use? Let us hear your requirements.Optical bonding will make a large difference in the viewability of your display screen.

Any questions are welcomed. Please feel free to contact us now!

Click here for inquiries about each department and product