Surface Treatment – UV

Intended Use of UV Treatment

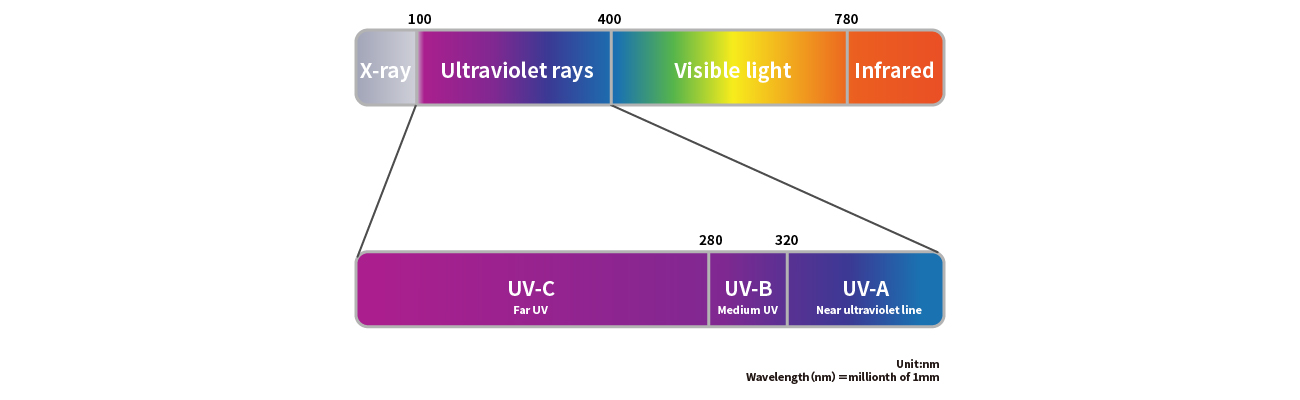

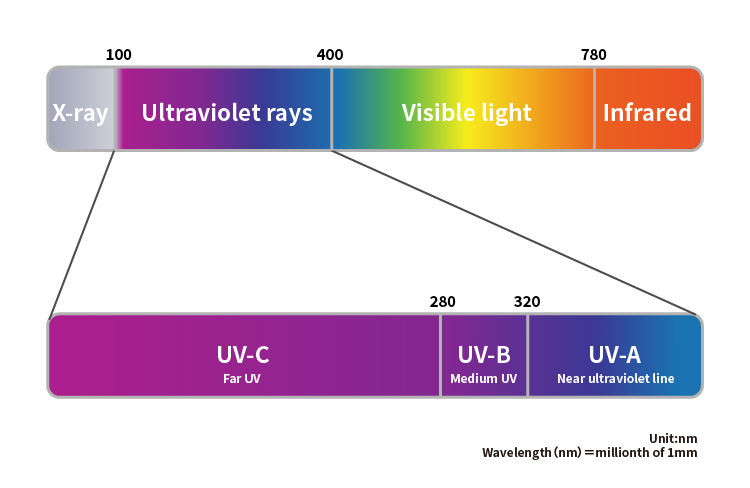

Ultraviolet (UV) light is invisible to the human eye as it has a short wavelength of 100~400 nm.

・UV-C (Short wavelength UV): Cleaning, Reforming the surface, Sterilization, Direct plating, Ozone generation

・UV-B (Medium wavelength UV): Curing, Analysis

・UV-A (Long wavelength UV): Curing

Low pressure UV (ultraviolet) Device

This equipment uses ultraviolet rays to clean, modify, and pre-plate the surfaces of resins, metals, and glass.

UV Irradiation Equipment KOL4-200

Usable for testing and low-volume production.

Batch processing equipment.

It can process sizes up to 350 × 140 mm.

UV irradiator KOL1-30H/I

For cleaning and surface modification with UV-C ultraviolet rays and ozone (air-cooled type).

It can be used for testing and small volume production, and comes with a lamp OFF timer.

Available in fixed or handheld versions.

You can choose from two types of lamps (ozoneless and ozone type).

It can process sizes up to 50 × 50 mm.

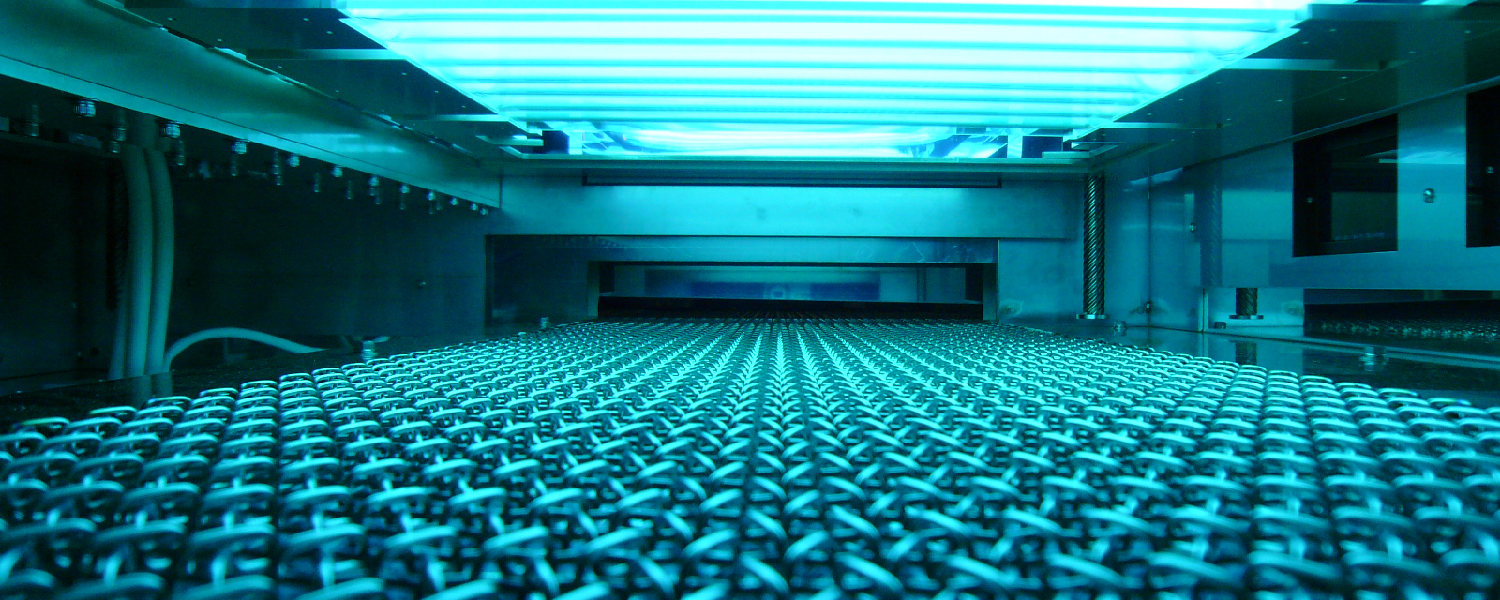

UV Surface Treatment Equipment KOL6-1200H/L

Capable of performing continuous UV treatment for a variety of sizes of 3D objects and sheet FPC material.

Applicable on up to 550mm-wide materials.

Usable from sample production to low-volume production.

UV Surface Treatment Equipment KOL2-1200V/R

Capable of performing continuous UV treatment for both surfaces of a variety of sizes of FPC material.

Applicable on up to 500mm-wide materials.

Usable from sample production to low-volume production.

High pressure UV (ultraviolet) Device

It is a device that cures and dries by using ultraviolet rays.

UV Irradiation Equipment KOH1-15H/L

Desktop-type UV cure equipment.

Applicable on up to 100mm-wide materials.

Usable from sample production to low-volume production.

2-step lamp output adjustment available.

Equipped with work cooling function.

UV Irradiation Equipment KOH1-45H/L

All-in-one type equipment.

Capable of performing continuous UV treatment for up to 300mm-wide materials.

2-step lamp output adjustment available.

Equipped with work cooling function.

UV-LED Device

Curing equipment that uses UV-LED to reduce running costs.

UV-LED Irradiation Device KOD-240A

It has a long life of 15,000 hours for the instant lighting type, instant stable light emission type, and dimming type.

The heat damage to the workpiece is greatly reduced, and it is energy-saving, mercury-free, and environmentally friendly.

UV (ultraviolet) Lamp

We have a wide range of UV lamp lineups for cleaning, reforming, and curing the surface.

Low-pressure Mercury Lamp (Low-pressure UV Lamp)

Discharge lamp which efficiently radiates UV-C (185nm & 254nm).

【Product form】

Selectable from Straight, U-shape, M-shape, and Grid type.

【Type】

Selectable from the following 3 types:

・Fused quartz: Generates more Ozone gas than Synthetic quartz does. 254nm, 185nm

・Synthetic quartz: Efficiently generates Ozone gas. 254nm, 185nm

・Ozone-Free: Does not generate Ozone gas, only 254nm

【Use】

Cleaning and reforming the surface of the films and resins, plating pretreatment, and cleaning glass and metals.

High-pressure Mercury Lamp (High-pressure UV Lamp) and Metal Halide Lamp

> High-pressure Mercury Lamp (High-pressure UV Lamp)

The discharge lamp for UV curing has the dominant wavelength of UV-A (365nm).

【Product form】

Straight type only

【Use】

Curing/Drying clear paints and adhesives, etc.

>Metal Halide Lamp

The discharge lamp has a wide spectrum (250 to 450nm).

【Product form】

Straight type only

【Use】

Curing UV inks for printing, etc.

Q&A

| What UV wavelengths are used for cleaning and reforming the surface? | 254nm and 185nm (UV-C). |

|---|---|

| What kind of materials can be cleaned effectively? | Glass, resins and metals, etc. |

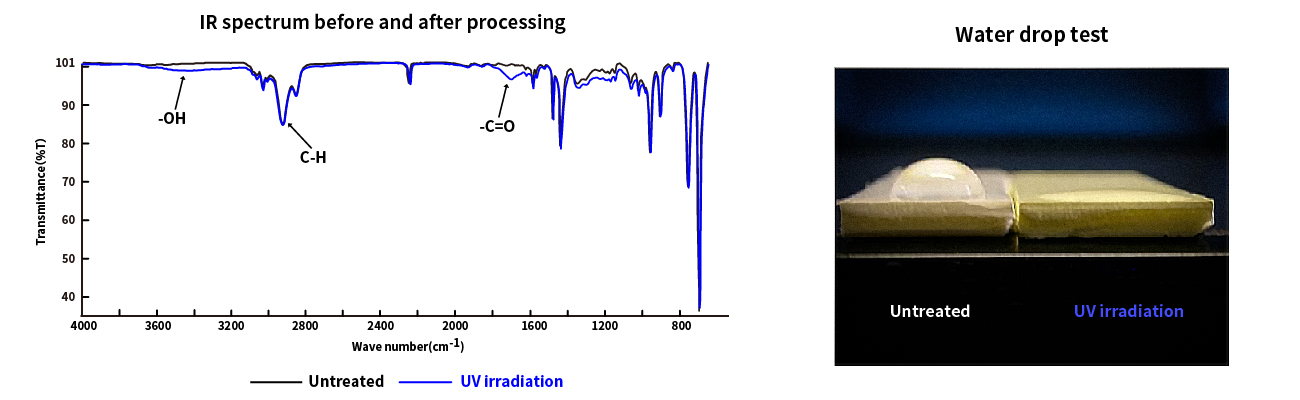

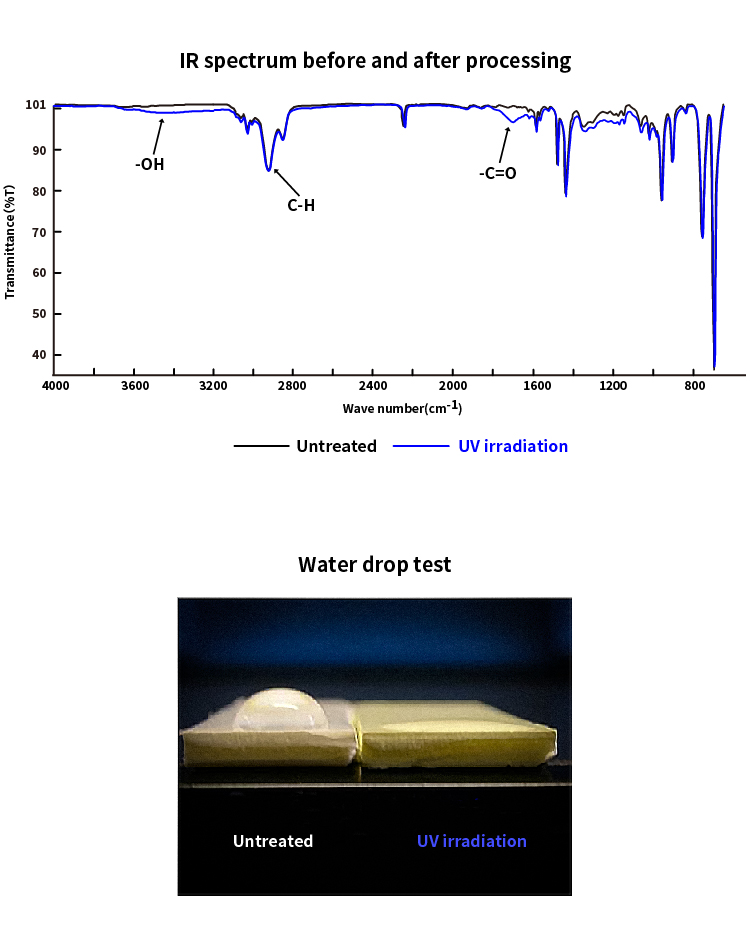

| What is cleaning and reforming the surface by UV? | Since the energy of UV (254 nm, 185 nm) is larger than the chemical bonding energy of organic materials such as resin, UV irradiation cleaves the bonds of organic substances; and at the same time, 185 nm UV produces ozone (O3) from atmospheric oxygen. When this ozone is irradiated with 254 nm UV, active oxygen is generated. The active oxygen volatilizes and removes (= cleans) organic matter into a gas such as CO2 by a continuous chemical reaction. Further, functional groups such as OH, COO, CO, and COOH are formed on the resin surface due to the influence of the active oxygen, thereby significantly improving the adhesiveness of the surface as the above functional groups have good compatibility with inks, adhesives and coating materials, etc. |

| How to check the effectiveness of UV? | Measure the contact angle of a water droplet to check the wettability. |

| What is a UV cure? | To harden the UV curable resin that is comprised of prepolymer, monomer, photoinitiator, and additive in a short time (for several to several tens of seconds) by irradiating UV from the 200-400nm high-pressure mercury (UV) lamp. |

|---|---|

| What is UV plating? | UV pretreatment + Electroless plating process. > Features of plating for circuit boards: 1. Copper foil or bonding sheet are not used. 2. Conductor loss can be reduced and fine-pitch circuit boards can be easily formed since plating is performed on a smooth surface. 3. Possible to plate on hard-to-plate materials including polyimide (PI), liquid crystal polymer (LCP), cycloolefin polymer (COP), etc. > Features of resin plating: 1. The smoothness of the surface of the material can be maintained since the surface property is reformed by UV irradiation without using chromic acid etching. 2. Possible to plate on hard-to-plate materials including polyphenylene sulfide (PPS), polyphenylene ether (PPE), polyamide (PA), etc. |

UV Plating Applications

Plating with UV irradiation pretreatment can be performed on various materials including the followings.

High-frequency antenna

Material: Cycloolefin polymer

FPC board for optical communication

Material: Liquid crystal polymer

Three-dimensional objects

Material: PBT, PPS

UV Plating Service, Prototyping

Please feel free to contact us for UV treatment for films, plates, 3D materials. etc. of various sizes.

We provide UV plating/treatment service (cleaning, reforming, curing the surface of materials with UV) to respond to our customers' requirements.

Click here for inquiries about each department and product